Home > Products > Compression Gasket Sheet Materials > PTFE Sheets > 60% Bronze Powder Filled PTFE TEFLON Sheet

60% Bronze Powder Filled PTFE TEFLON Sheet

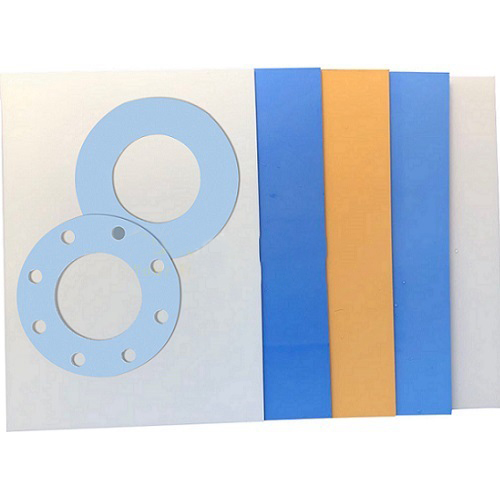

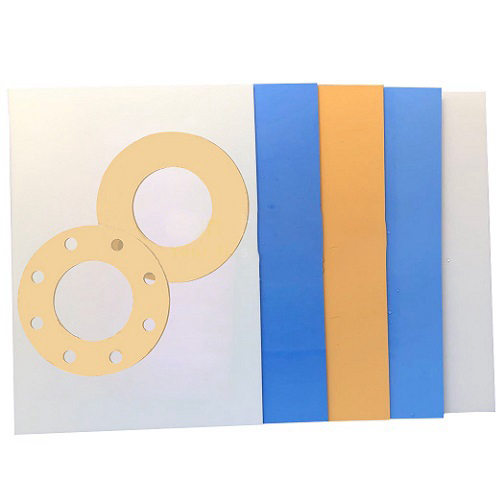

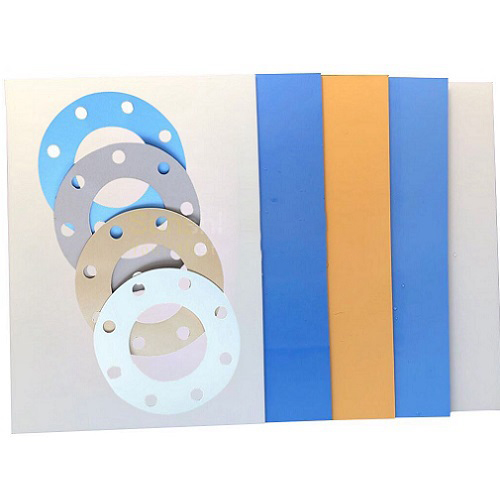

60% bronze powder filled PTFE TEFLON Sheet is the most popular PTFE compound which has 60% bronze mixed with 40% PTFE, it is dark brown in color

Send Inquiry

Product Description

60% Bronze Powder Filled PTFE TEFLON Sheet - Kaxite 2240

60% bronze powder filled PTFE TEFLON Sheet is the most popular PTFE compound which has 60% bronze mixed with 40% PTFE, it is dark brown in color. 60% Bronze Powder Filled PTFE Moulded sheet has excellent wears, creep resistance, and higher thermal conductivity than glass fiber with PTFE. PTFE materials often have defects such as non-wear resistance, poor mechanical properties, and easy creep. Fillers need to be added to improve their performance. And adding a certain amount of tin bronze filling is a common method. 60% bronze powder filled PTFE TEFLON Sheet can greatly improve the thermal conductivity, wear resistance and pressure resistance of PTFE. Adding tin bronze powder will increase the bearing capacity of the composite material; increase the friction coefficient; reduce the wear loss of the composite material, that is, increase the wear resistance; improve the thermal conductivity of the product, and can be made into plates, rods, Tubes and other special-shaped parts. So what are the effects of the particle size, shape and quality performance of the bronze copper powder, as well as the proportion of the added bronze copper powder, and the operation method on the filled products?Compared with graphite added to PTFE, the hardness of copper powder added to PTFE is relatively harder, but the wear resistance of graphite added is better than copper powder added, and the friction coefficient of the composite material added with graphite is also Better than copper powder filled with PTFE. The smaller the particle size of the copper powder, the tensile strength and elongation will increase, and the hardness or compression will decrease slightly as the particle size becomes smaller. The larger the particle size of the copper powder, the worse the wear resistance of the composite product. In addition, the irregular particle size copper powder filled PTFE products have better mechanical properties, while the round particle size bronze copper powder has relatively better Wear resistance. increasing the proportion of filled copper powder in the composite material will reduce the tensile strength and elongation of the product, but its hardness and compression resistance will increase, and the overall proportion will also increase. Bronze copper powder itself is a kind of soft metal, it is not easy to damage the mating part during friction, and the heat dissipation effect is better and it is more suitable for the working environment where friction generates heat.

Hot Tags: 60% Bronze Powder Filled PTFE TEFLON Sheet, China, Manufacturers, Suppliers, Factory, Wholesale

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.