Home > Products > Industrial Sealing Gaskets > Copper Metal Gaskets > Copper Exhaust Manifold Gaskets

Copper Exhaust Manifold Gaskets

The HS Code for copper exhaust manifold gaskets is 73269090.00, you also can know how to install this kind of gasket here.

Send Inquiry

Product Description

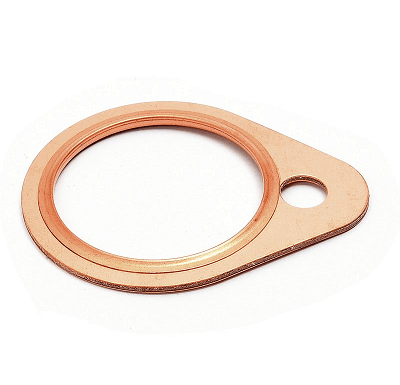

Style CU15 - Copper Exhaust Manifold Gaskets

As major copper exhaust manifold gaskets makers, we know copper is amongst the most effective exhaust gasket materials in the marketplace. A good copper exhaust gasket could be the frequent option for numerous applications, and also you can find a valid reason for this. It offers a lot of exceptional characteristics and also advantages.Copper exhaust manifold gaskets directly impact the performance of your engine. You would like to be certain that your exhaust device is sealed at every interconnection point. Through the cylinder block and manifold to your catalytic converter as well as beyond, a new properly sealed system warranties the greatest results.

If you want a new accuracy and precision made personalized copper exhaust manifold gasket that functions underneath the most stressful conditions, Each of our product is your full fulfillment and a copper exhaust gasket that exceeds your expectations.

The Copper Advantage

Copper is an ideal exhaust manifold gasket material for many causes. That performs and also distributes heat consistently, can avoid warping. It is strong but malleable. It creates a tight seal as well as reduces leaks. It limits sizzling hot areasEven though stainless steel or any other really hard precious metals may look stronger, copper is a perfect material for your specialized manufactured exhaust gasket. Its own distinctive attributes give it time to produce a firmer seal that will conforms to any surface and reduce extra mobility. It is long-lasting to stand up to large amounts of wear as well as it resists rust.

Gaskets are actually precision components which need to offer under high stress conditions. Whichever your gasket program is, you need a company you can rely as well as materials you can will depend on

The other materials for exhaust manifold gaskets could be: graphite, stainless steelundefined

Steps to Install Copper Exhaust Manifold Gaskets

1. Figure out the shape and size of the header or manifold opening. The shape of your cylinder head exhaust port is of secondary matter if you find enough sealing surface area for the header opening.2. Select the right copper exhaust gasket which most closely satisfies the size and shape of the header or manifold opening. Ensure the embossed sealing bead aligns with the raised weld bead of the header sealing surface when put together.

3. Neat and lubricate the threads in the cylinder head so full clamping is definitely attained when bolts tend to be torqued. After the gasket is fully seated the bolts will likely not release considering that the gasket is reliable metallic and may not shrink from repetitive heating cycling.

4. Set up gaskets and torque to standards. Appropriate torque for new lubricated 3/8 x 16 standard 5 bolts is 23 to 31 ft lbs.

Hot Tags: Copper Exhaust Manifold Gaskets, China, Manufacturers, Suppliers, Factory, Wholesale

Related Category

Sanitary Tri-clamp Gaskets

Copper Metal Gaskets

Kammprofile Gaskets

Silver Gasket

Metal Jacketed Gaskets

PTFE Gasket Washer

Non-asbestos Fiber Gasket

Flexible Graphite Gasket

Ring Type Joint Gasket

Spiral Wound Gaskets

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.